The following is the DG200 granulation plan. One set of DG200 capacity is 0.9~1.2 t/h. The output was calculated according to ammonium chloride. The yields of different materials were different. DG series, as well as DG350 type production is higher, the following layout program for users only, specific layout, my company technical personnel can be in accordance with user requirements, do detailed design

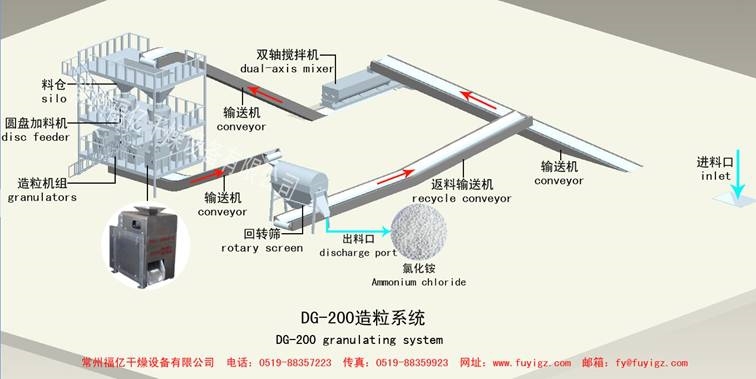

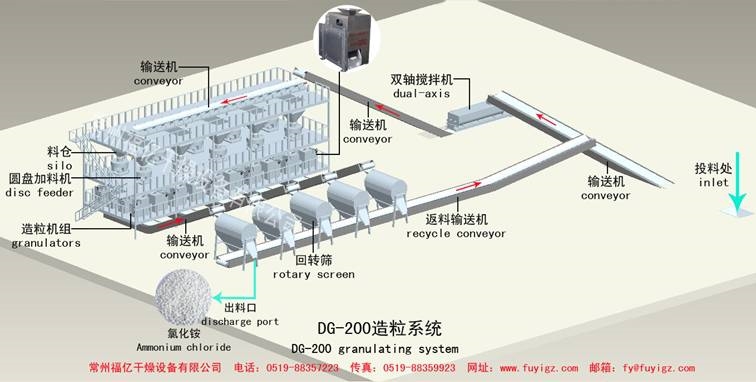

1、Flow chat of DG200 granulation line with 4t/h.

|

No. |

Name |

Specifications |

Material |

Qty. |

Note |

|

1 |

Mixer |

φ2200 |

Q235 |

1 |

Motor 11KW |

|

2 |

Disc feeder |

|

Q235 |

1 |

Motor 1.5KW |

|

3 |

Granulator DG200 |

|

|

4 |

Motor 15KW,The main reducer adopts hard toothed surface and double shaft output |

|

4 |

Screen machine |

φ1.5×4 |

Q235 |

1 |

Motor 2.2KW |

|

5 |

Cnveyor |

|

Q235 |

4 |

fabrication on site |

|

6 |

Control cabinet |

|

Q235 |

1 |

Centralized control operation of granulation system |

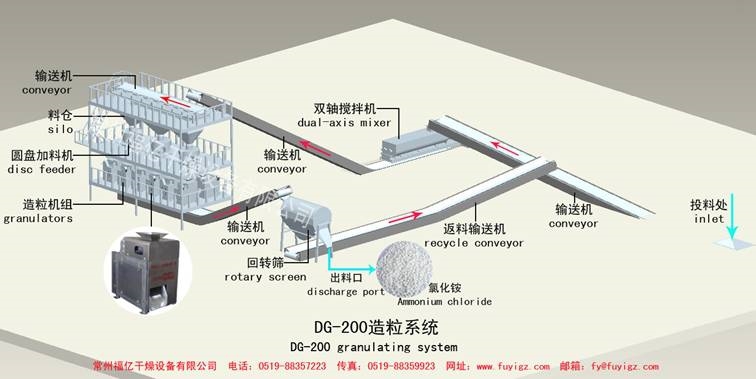

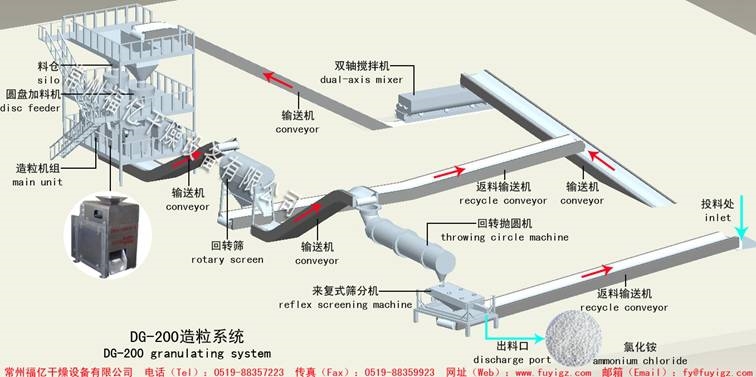

2、Flow chat of DG200 granulation line with 8t/h.

|

No. |

Name |

Specifications |

Material |

Qty. |

Note |

|

1 |

Dual-axis mixer |

500 type |

Q235 |

1 |

Motor 11KW |

|

2 |

disc feeder |

|

Q235 |

2 |

Motor 1.5KW |

|

3 |

Granulator DG200 |

|

|

8 |

Motor 15KW,The main reducer adopts hard toothed surface and double shaft output |

|

4 |

Screen machine |

φ1.5×4 |

Q235 |

1 |

Motor 2.2KW |

|

5 |

Conveyor |

|

Q235 |

4 |

fabrication on site |

|

6 |

Control cabinet |

|

Q235 |

1 |

Centralized control operation of granulation system |

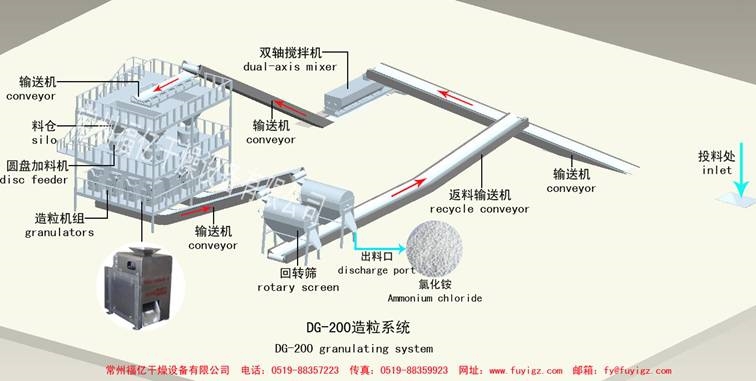

3、Flow chat of DG200 granulation line with 12t/h.

|

No. |

Name |

Specifications |

Material |

Qty. |

Note |

|

1 |

Dual-axis mixer |

500 type |

Q235 |

1 |

Motor 11KW |

|

2 |

disc feeder |

|

Q235 |

3 |

Motor 1.5KW |

|

3 |

Granulator DG200 |

|

|

12 |

Motor 15KW,The main reducer adopts hard toothed surface and double shaft output |

|

4 |

Screen machine |

φ1.5×4 |

Q235 |

1 |

Motor 2.2KW |

|

5 |

Conveyor |

|

Q235 |

4 |

fabrication on site |

|

6 |

Control cabinet |

|

Q235 |

1 |

Centralized control operation of granulation system |

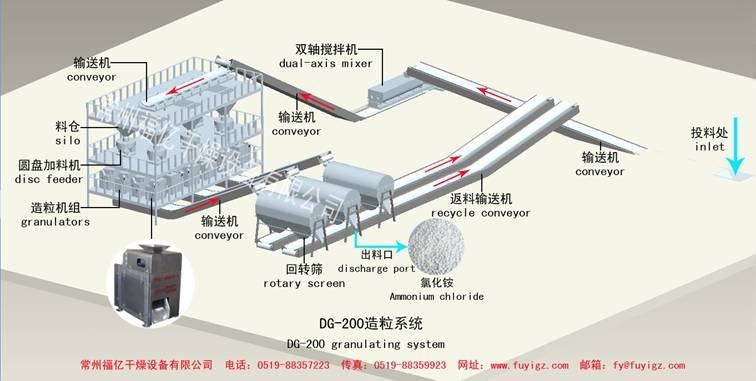

4、Flow chat of DG200 granulation line with 16t/h.

|

No. |

Name |

Specifications |

Material |

Qty. |

Note |

|

1 |

Dual-axis mixer |

500 type |

Q235 |

1 |

Motor 11KW |

|

2 |

disc feeder |

|

Q235 |

4 |

Motor 1.5KW |

|

3 |

Granulator DG200 |

|

|

16 |

Motor 15KW,The main reducer adopts hard toothed surface and double shaft output |

|

4 |

Screen machine |

φ1.5×4 |

Q235 |

1 |

Motor 2.2KW |

|

5 |

Conveyor |

|

Q235 |

4 |

fabrication on site |

|

6 |

Control cabinet |

|

Q235 |

1 |

Centralized control operation of granulation system |

5、Flow chat of DG200 granulation line with 24t/h.

|

No. |

Name |

Specifications |

Material |

Qty. |

Note |

|

1 |

Dual-axis mixer |

500 type |

Q235 |

1 |

Motor 11KW |

|

2 |

disc feeder |

|

Q235 |

6 |

Motor 1.5KW |

|

3 |

Granulator DG200 |

|

|

32 |

Motor 15KW,The main reducer adopts hard toothed surface and double shaft output |

|

4 |

Screen machine |

φ1.5×4 |

Q235 |

3 |

Motor 2.2KW |

|

5 |

Conveyor |

|

Q235 |

7 |

fabrication on site |

|

6 |

Control cabinet |

|

Q235 |

1 |

Centralized control operation of granulation system |

6、Flow chat of DG200 granulation line with 40t/h.

|

No. |

Name |

Specifications |

Material |

Qty. |

Note |

|

1 |

Dual-axis mixer |

500 type |

Q235 |

1 |

Motor 11KW |

|

2 |

disc feeder |

|

Q235 |

10 |

Motor 1.5KW |

|

3 |

Granulator DG200 |

|

|

40 |

Motor 15KW,The main reducer adopts hard toothed surface and double shaft output |

|

4 |

Screen machine |

φ1.5×4 |

Q235 |

5 |

Motor 2.2KW |

|

5 |

Conveyor |

|

Q235 |

9 |

fabrication on site |

|

6 |

Control cabinet |

|

Q235 |

1 |

Centralized control operation of granulation system |

7、Can also be added throwing round screening equipment, so that particles more smooth and rounded

8、If the particle moisture is large, you need to dry, you can use the following process:

Mobile: 0086-18706143009 Tel: 0086-519-80181222 Address:No.212,Huaxing Road, Jintan Development Zone, Changzhou City, Jiangsu Province, China

Copyright ©2016 Jiangsu Fuyi Machinery Technology Co., Ltd [Manage]