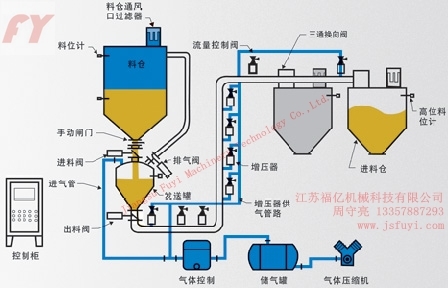

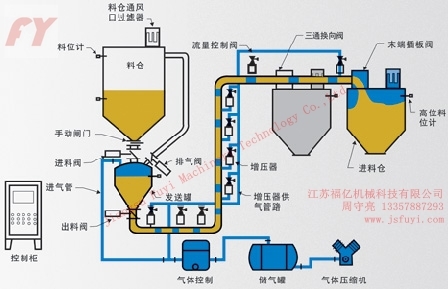

1. Principle:

During feeding, the material is added to the delivery tank by gravity through the bell valve, double butterfly valve or expansion butterfly valve, and the displaced air is released through the exhaust valve, which makes feeding easier. As soon as the delivery tank is filled (by means of a material level meter or weighing shows that the material reaches 80% of the tank volume), the feed valve and the exhaust valve are closed and sealed at the same time.

The gas source of the pipeline booster is supplied by another set of attached pipes. The main function of the pipeline is to provide air supply for the supercharger on the main conveying pipeline. When the booster is pressurized in the main pipe, the material in the conveying pipeline is prevented from entering the booster and the attached pipe through its internal check mechanism. For materials which are difficult to convey or have a large proportion, the installation distance between the turbochargers is nearer, but vice versa. When the material in the pipeline is close to empty, the pressure drop in the tank is zero. At this point, the gas supply valve is closed immediately, while the remaining gas is discharged from the pipeline.

2. Applicable material:

This method is suitable for long transmission lines and fine, granular, abrasive and non abrasive and other materials which are difficult to transport. Such as quartz sand, refractory material, soda powder, fluorspar powder, aluminium fluoride, silica powder and so on.

3.Component:

The system is mainly composed of a delivery tank, a pipeline, a pipeline, a supercharger and an electronic control part.

4. Characteristic:

The system features a moderate gas flow rate and a lower delivery pressure throughout the delivery process.

5、Process flow diagram

Mobile: 0086-18706143009 Tel: 0086-519-80181222 Address:No.212,Huaxing Road, Jintan Development Zone, Changzhou City, Jiangsu Province, China

Copyright ©2016 Jiangsu Fuyi Machinery Technology Co., Ltd [Manage]